MAKING OF THE BOW: THE STRING PAD

WHEN IN THE 16TH CENTURY AD MANCHURIAN WARRIORS ATTACKED CHINA THEY WERE ARMED WITH HIGHER QUALITY AND MORE EFFECTIVE BOWS THAN THEIR ADVERSARIES. SIX CENTURIES EARLIER, IN THE TIME OF THE MONGOLS, THE SOUTHERN TERRITORIES OF MANCHURIA WERE FAMOUS FOR THEIR ARROW-MAKING INDUSTRY. IT MIGHT HAVE BEEN DUE TO THE OUTSTANDING CRAFTSMANSHIP TRADITIONS THAT DURING THIS ERA THE MANCHURIANS WERE ABLE TO DEVELOP A SLIGHT INNOVATION IN THE BOW THAT WOULD RENDER AIMING SIGNIFICANTLY MORE ACCURATE, THE MANCHURIAN STRING-PAD.

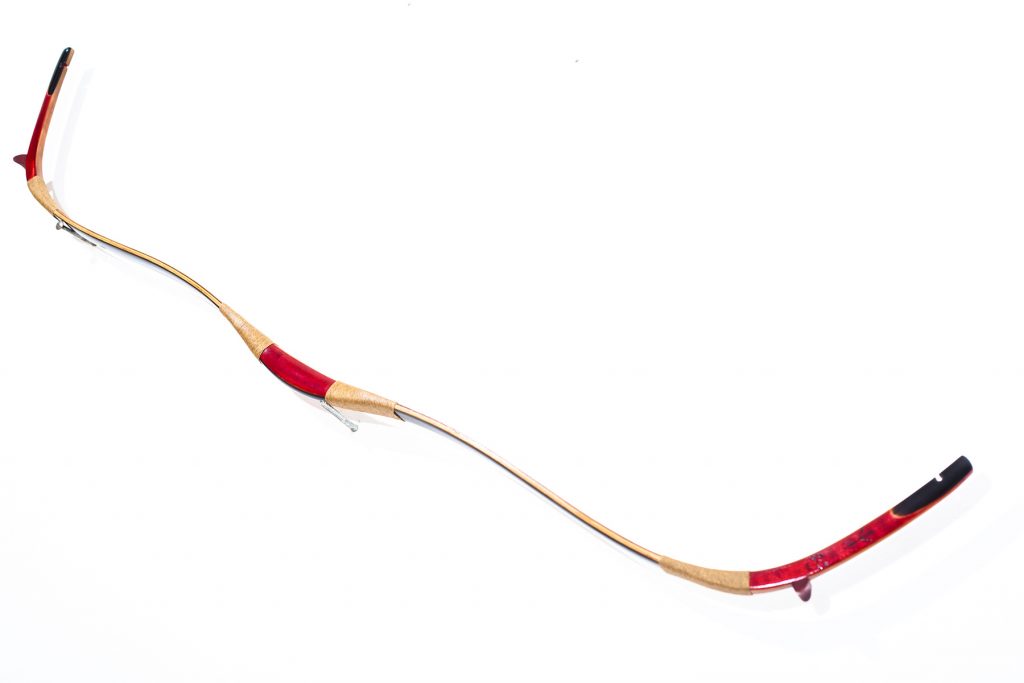

The Manchurian-type recurve bow was equipped with a string pad underneath both of the bow tips. The Manchurian string-pad was a sort of bone-knob with a semicircular groove for the bow-string. It was fixed onto the bone bow-tip, on the internal side of the bow facing the archer. Its formation was a lot like that of the wooden bridge on violins or other stringed instruments. On the bow equipped with a string pad, the string is longer, which renders the entire construction more flexible without having to decrease the stiffness of the Khitaj bow-type. The fork-shaped performance of the string pad allays the sideward amplitudes of the string both when aiming and when the string snaps back.

The Manchurian-type recurve bow was equipped with a string pad underneath both of the bow tips. The Manchurian string-pad was a sort of bone-knob with a semicircular groove for the bow-string. It was fixed onto the bone bow-tip, on the internal side of the bow facing the archer. Its formation was a lot like that of the wooden bridge on violins or other stringed instruments. On the bow equipped with a string pad, the string is longer, which renders the entire construction more flexible without having to decrease the stiffness of the Khitaj bow-type. The fork-shaped performance of the string pad allays the sideward amplitudes of the string both when aiming and when the string snaps back.

The Manchurian therefore, with this minor change in the bow-structure, could still improve the effectiveness of this ancient weapon even in the time of gunpowder and firearms. They are not only credited with this innovation because the phenomenon had appeared during the time of their campaigns, but because the original name of the string pad, the “tebke” spread from Manchurian into the language of other steppe-dwelling nations, into Mongolian, and partly into the Turkish language as well. Moreover, the string-pad is always to be found on the simple-structured bows of the Manchurian or the bows of other nations living along the river Amur, while it has not spread to the west or south of the steppes, to central Europe or the Near East for instance. However, during the 17th Century AD, it did become popular in the Russian territories. The most abundant and contiguous material dealing with the arrows of this era was found in the multilingual dictionaries compiled by the Manchurian monarchs.

In the time of creation of these multilingual dictionaries bows still had great significance as weapons— they hadn’t yet become as over-sophisticated as the expensive creations of the Muslim craftsmen. Custom-made or unique examples of renowned masters were of course encountered among the Manchurian recurve bows as well; most bows, however, were manufactured by ordinary craftsmen.

In the time of creation of these multilingual dictionaries bows still had great significance as weapons— they hadn’t yet become as over-sophisticated as the expensive creations of the Muslim craftsmen. Custom-made or unique examples of renowned masters were of course encountered among the Manchurian recurve bows as well; most bows, however, were manufactured by ordinary craftsmen.

The first step of bow-making was to carve out—as they put it— the “curves” or shape of the bow from wood— most frequently from birch wood. The quality of the wood had a significant effect on the bow’s features. If the basis, or wooden core, was made of quality wood the result was an “obedient”, flexible bow, otherwise “the inside was hard as a rock”: in other words, the bow would prove too stiff. The handle was configured in the centre of the wooden core in a way that its shape would fit the archer’s palm: most frequently it was a triangle-prism to which three bone-plates were fixed. (In earlier times there had been two or four bone-plates fixed to the handle in fact.) When nocking the arrow, the tensile force of the two flexible limbs caused a sharp bend on the two sides of the handle.

The place where the parts of the limbs joined received particular attention: first they carved grooves into the flexible limbs, then they developed bolts at the end of the stiff limbs, and finally they slid the two pieces into one another. The cross-section of the stiff limbs was triangular. After the wooden core had been done, a sinew layer was added onto its external side.

The animal-sinews were cleaned of all the fat—they were most frequently made of cattle or deer—and were pressed onto the wood in multiple layers—at times in as many as six layers so the that the bow would become even more resistant. Of course, new layers could be added only when the previous ones had already dried. The drying of one sinew-layer could take from 6 up to 16 days depending on the season, warmth and humidity.

There was a slight rise on the external side of the bow where the sinews were fixed. This mound created by the sinews was called the “sacrum” or “cross-bone”, by the Manchurians, while the Mongolian named it the “mouth-pad”, the Tibetans referred to it as “the stairs of the bow”, and the Chinese called it “the bow’s mind”.

Onto the internal side of the bow facing the archer, 5 to 7 centimetres long, flexible plates were glued. In case of ordinary bows these were made of cattle horn, but in other cases, yak or rock-goat horn, moose antler, or other flexible materials were used, such as hoof horn, tortoiseshell, whalebone, etc. The Mongolians, strangely, named this bone-layer “the bow’s liver”.

The innovation of the Manchurians, the string-pad, was glued to the bony side of the bow at the end of the stiff limbs. It consisted of a bone-disk and on top of it, a semicircular, concave “fork”. To the end of the stiff limbs, the bow-tip or end-piece was attached. The Manchurian and the Mongolian called it “the nose”, while the Turks referred to it as “the head”. It was made of very hard wood or bone and was provided with a semi-circular groove that served for the nocking of the string. (At times on the nocking-side there could even be two grooves on one tip.) Once the “nose” was fixed, the bow was ready.

Then it was polished from top to bottom, cleaned and glazed— especially the internal horn-layers. Finally, it was plastered with liquid fish-glue and was wrapped around with strips of birch-bark. Not only did the birch-bark coating serve to ornament the bow, but it protected the sensitive sinew-layer from getting wet. Bows decorated with birch-bark wrapping can frequently be seen in the contemporary Inner-Asian and Chinese representations, but the Turkish records mention it as well.

Once the bow was done, it would undergo a certain test-nocking procedure. It would be strung contrary to its natural shape and direction as is usual in the case of reflex-bows. The string material of this era was already a compound: a string made of animal intestine plaited with silk-threads with two leather-loops at the two ends. The string of the nocked bow was twanged to see whether it was tense enough. This was the key moment when the quality of the brand-new bow was set—whether it worked out well or it needed some additional refinements. After testing the arrow, all the joints were, according to requirements, wrapped around with sinews or some more strings.